End Grain versus Edge Grain Wood Cutting Boards

It’s not about the price, but the purpose.

Edge Grain Cutting Boards

Edge grain cutting boards make up 90% of our inventory. These boards are perfect for everyday cutting, light to medium use and as serving charcuterie boards. These boards are typically thinner and you can see the grain is in a more linear, horizontal pattern.

They are made by gluing together the long sides of the board in a parallel pattern.

These boards are durable, however they tend to dull your knives faster than end grain cutting boards. These boards will end up having cut marks which you can minimize by using our Mineral oil and beeswax protective coat for longer lasting protection. This cut of wood is what most cutting boards are made of because it is more economical and easier to make than end grain boards.

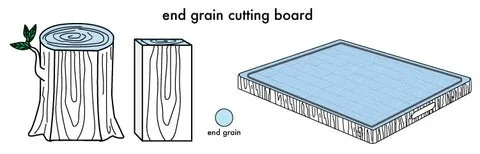

End Grain Cutting Boards

This type of cutting board is mainly characterized by a checkerboard pattern and seeing the rings of the tree. It is made using end pieces of wood, glued and clamped together. These boards are often more expensive as they are of a higher durability, better for heavy cutting and easier on your chefs knives. These types of boards are ideal for butcher shops, chefs kitchens and serious cooking hobbyists.

They are not ideal for serving charcuterie as they are thick and heavy.

These boards are longer lasting as they can be sanded and restored much more easily over decades of use than edge grain boards.

They are more expensive, but worth the investment.